Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Modelo: GB 9948

marca: Torich

Pacote: Embalagem em caixas de madeira ou em feixes hexagonais

produtividade: 20000 Tons per Year

transporte: Ocean,Land,Air

Lugar de origem: China

Apoio sobre: 60000 Ton per year

Certificados : ISO9001:2008 ISO14001:2008, TS16949, CE PED, TUV, API

Código HS: 7304293000

porta: Shanghai,Ningbo

Tipo de pagamento: L/C,T/T,D/P,Paypal,Money Gram,Western Union

Incoterm: FOB,CFR,CIF,FCA,CPT

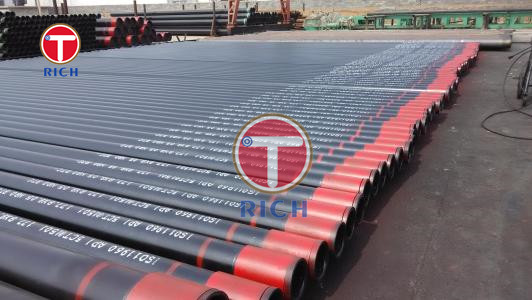

Nome do produto: GB 9948 Material10 # 20 # 12CrMo 15CrMo 12Cr1MoV Petróleo Tubos De Aço Sem Costura de Rachamento

Nós somos fabricante de tubos de aço sem costura na China, se você quiser comprar tubo de aço carbono sem costura, tubo de aço cilindro de óleo, tubo de aço sem costura de precisão, tubo de aço do cilindro hidráulico, entre em contato conosco.

Fora do diâmetro: 3 ~ 600mm

Espessura da parede: 0.5 ~ 50mm

Aplicação: É usado para os tubos de aço sem costura para forno, trocadores de calor de Petróleo Craqueamento etc.

Tabela 1 As Tolerâncias do Diâmetro Externo e da Unidade de Espessura da Parede : mm

|

Sort Code |

Manufacuring Method |

Nominal Size |

Tolerances |

||

|

Common Level |

High Level |

||||

|

W-H |

Hot Rolling (Extrusion) |

Outer Diameter D |

≤54 |

±0.50 |

±0.30 |

|

>54~325 |

±1%D |

±0.75%D |

|||

|

>325 |

±1%D |

- |

|||

|

Wall Thicknass S |

≤20 |

+15%S -10%S |

±10%S |

||

|

>20 |

+12.5%S -10%S |

±10%S |

|||

|

Hot Expand |

Outer Diameter D |

All |

±1%D |

||

|

Wall Thicknass S |

All |

±15%S |

|||

|

W-C |

Cold Drawn(Rolling) |

Outer Diameter D |

≤25.4 |

±0.15 |

|

|

>25.4~40 |

±0.20 |

||||

|

>40~50 |

±0.25 |

||||

|

>50~60 |

±0.30 |

||||

|

>60 |

±0.75%D |

±0.5%D |

|||

|

Wall Thicknass S |

≤3.0 |

±0.3 |

±0.2 |

||

|

>3.0 |

±10%S |

±7.5%S |

|||

Tabela 2 A Tolerância da Unidade Espessura Mínima da Parede: mm

|

Sort Code |

Manufacturing Method |

Minimum Wall Thickness Smin |

Tolerance |

|

|

Common Level |

High Level |

|||

|

W-H |

Hot Rolling(Extrusion) |

≤4.0 |

+0.90 0 |

+0.70 0 |

|

>4.0 |

+25%Smin 0 |

+22%Smin 0 |

||

|

W-C |

Cold Drawn(Rolling) |

≤3.0 |

+0.6 0 |

+0.4 0 |

|

>3.0 |

+20%Smin 0 |

+15%Smin 0 |

||

Tabela 3 Classe de aço e composição química

|

Steel grade |

Chemical composition % |

|||||||||||

|

C |

Si |

Mn |

Cr |

Mo |

Ni |

Nb |

Ti |

V |

Cu |

P |

S |

|

|

≤ |

||||||||||||

|

10 |

0.07~ 0.13 |

0.17~ 0.37 |

0.35~ 0.65 |

≤0.15 |

≤0.15 |

≤ 0.25 |

- |

- |

≤0.08 |

≤0.20 |

0.025 |

0.015 |

|

20 |

0.17~ 0.23 |

0.17~ 0.37 |

0.35~ 0.65 |

≤0.25 |

≤0.15 |

≤ 0.25 |

- |

- |

≤0.08 |

≤0.20 |

0.025 |

0.015 |

|

12CrMo |

0.08~ 0.15 |

0.17~ 0.37 |

0.40~ 0.70 |

0.40~ 0.70 |

0.40~ 0.55 |

≤ 0.30 |

- |

- |

- |

≤0.20 |

0.025 |

0.015 |

|

15CrMo |

0.12~ 0.018 |

0.17~ 0.37 |

0.40~ 0.70 |

0.80~ 1.10 |

0.40~ 0.55 |

≤ 0.30 |

- |

- |

- |

≤0.20 |

0.025 |

0.015 |

|

12CrlMo |

0.08~ 0.15 |

0.50~ 1.00 |

0.30~ 0.60 |

1.00~ 1.50 |

0.45~ 0.65 |

≤ 0.30 |

- |

- |

- |

≤0.20 |

0.025 |

0.015 |

|

12CrlMoV |

0.08~ 0.15 |

0.17~ 0.37 |

0.40~ 0.70 |

0.90~ 1.20 |

0.25~ 0.35 |

≤ 0.30 |

- |

- |

0.15~ 0.30 |

≤0.20 |

0.025 |

0.015 |

|

12Cr2Mo |

0.08~ 0.15 |

≤0.50 |

0.40~ 0.60 |

2.00~ 2.50 |

0.90~ 1.13 |

≤ 0.30 |

- |

- |

- |

≤0.20 |

0.025 |

0.015 |

|

12Cr5MoI 12Cr5MoNT |

≤ 0.15 |

≤0.50 |

0.30~ 0.60 |

4.00~ 6.00 |

0.45~ 0.60 |

≤ 0.60 |

- |

- |

- |

≤0.20 |

0.025 |

0.015 |

|

12Cr9MoI 12Cr9MoNT |

≤ 0.15 |

0.25~ 1.00 |

0.30~ 0.60 |

8.00~ 10.00 |

0.90~ 1.10 |

≤ 0.60 |

- |

- |

- |

≤0.20 |

0.025 |

0.015 |

|

07Cr19Ni10 |

0.04~ 0.10 |

≤ 1.00 |

≤2.00 |

18.00~ 20.00 |

- |

8.00~ 11.00 |

- |

- |

- |

- |

0.030 |

0.015 |

|

07Cr18Ni11Nb |

0.04~ 0.10 |

≤ 1.00 |

≤2.00 |

17.00~ 19.00 |

- |

9.00~ 12.00 |

8C~ 1.10 |

- |

- |

- |

0.030 |

0.015 |

|

07Cr19Ni11NTi |

0.04~ 0.10 |

≤0.75 |

≤2.00 |

17.00~ 20.00 |

- |

9.00~ 13.00 |

- |

4C~ 0.60 |

- |

- |

0.030 |

0.015 |

|

022Cr17Ni12Mo2 |

≤ 0.30 |

≤1.00 |

≤2.00 |

16.00~ 18.00 |

2.00~ 3.00 |

10.00~ 14.00 |

- |

- |

- |

- |

0.030 |

0.015 |

Tabela 4 Padrão de Tratamento Térmico

|

Steel Grade |

Heat Treatment Standard |

|

10a |

Normalizing;At Temperature 880℃~940℃ |

|

20a |

Normalizing:At Temperature 880℃~940℃ |

|

12CrMob |

Normalizing:At Temperature 900℃~960℃ Tempering:At Temperature 670℃~730℃ |

|

15CrMob |

Normalizing:At Temperature 900℃~960℃ Tempering:At Temperature 680℃~730℃ |

|

12Cr1Mob |

Normalizing:At Temperature 900℃~960℃ Tempering:At Temperature 680℃~750℃ |

|

12Cr1MoVb |

S≤30mm:Normalizing:At Temperature 980℃~1020℃ Tempering:At Temperature 720℃~760℃ S>30mm:Quenching:At Temperature 950℃~990℃ Tempering:At Temperature 720℃~760℃ Or Normalizing:At Temperature 980℃~1020℃ (rapid cooling after Normalizing) Tempering:At Temperature 720℃~760℃ |

|

12Cr2Mob |

S≤30mm:Normalizing:At Temperature 900℃~960℃ Tempering:At Temperature 700℃~750℃ S>30mm:Quenching:At Temperature ≥ 900℃ Tempering:At Temperature 700℃~750℃ Or Normalizing:At Temperature 900℃~960℃ (rapid cooling after Normalizing) Tempering:At Temperature 700℃~750℃ |

|

12Cr5MoI |

Full Annealing or isothermal annealing |

|

12Cr5MoNT |

Normalizing:At Temperature 930℃~980℃ Tempering:At Temperature 730℃~770℃ |

|

12Cr9MoI |

Full Annealing or isothermal annealing |

|

12Cr9MoNT |

Normalizing:At Temperature 890℃~950℃ Tempering:At Temperature 720℃~800℃ |

|

07Cr19Ni10 |

Treatment with solid solving:At Temperature ≥ 1040℃ (rapid cooling after Treatment)

|

|

07Cr18Ni11Nb |

Treatment with solid solving: For Hot Rolled Tube At Temperature ≥ 1050℃ For Cold Drawn(rolled)Tube At Temperature ≥ 1100℃ (rapid cooling after Treatment)

|

|

07Cr19Ni11Ti |

Treatment with solid solving: For Hot Rolled Tube At Temperature ≥ 1050℃ For Cold Drawn(rolled)Tube At Temperature ≥ 1100℃ (rapid cooling after Treatment)

|

Tabela 5 Propriedade Mecânica

|

Steel Grade |

Tensile Strength Rm/MPa |

Lower yield strength Rp0.2/MPa |

Elongation A/% |

Shock absorption KV2/J |

Brinell hardness |

||

|

Longitudinal direction |

Transverse |

Longitudinal direction |

Transverse |

||||

|

≥ |

≤ |

||||||

|

10 |

335~475 |

205 |

25 |

23 |

40 |

27 |

- |

|

20 |

410~550 |

245 |

24 |

22 |

40 |

27 |

- |

|

12CrMo |

410~560 |

205 |

21 |

19 |

40 |

27 |

156HBW |

|

15CrMo |

440~640 |

295 |

21 |

19 |

40 |

27 |

170HBW |

|

12Cr1Mo |

415~560 |

205 |

22 |

20 |

40 |

27 |

163HBW |

|

12Cr2MoV |

470~640 |

255 |

21 |

19 |

40 |

27 |

179HBW |

|

12Cr2Mo |

450~600 |

280 |

22 |

20 |

40 |

27 |

163HBW |

|

12Cr5MoI |

415~590 |

205 |

22 |

20 |

40 |

27 |

163HBW |

|

12Cr5MoNT |

480~640 |

280 |

20 |

18 |

40 |

27 |

- |

|

12Cr9MoI |

460~640 |

210 |

20 |

18 |

40 |

27 |

179HBW |

|

12Cr9MoNT |

590~740 |

390 |

18 |

16 |

40 |

27 |

- |

|

07Cr19Ni10 |

≥520 |

205 |

35 |

- |

- |

187HBW |

|

|

07Cr18Ni11Nb |

≥520 |

205 |

35 |

- |

- |

187HBW |

|

|

07Cr19Ni11Ti |

≥520 |

205 |

35 |

- |

- |

187HBW |

|

|

022Cr17Ni12Mo2 |

≥485 |

170 |

35 |

- |

- |

187HBW |

|

|

If the wall thickness of the tube is less than 5mm, doesn`t have to do the hardness test |

|||||||

Tabela6 Fator de atenuação da absorção de energia de impacto da amostra pequena

|

Specimen |

Specimen size(heightXwidth)mm |

Attenuation factor |

|

Standard sample |

10X10 |

1.00 |

|

Small sample |

10X7.5 |

0.75 |

|

Small sample |

10X5 |

0.50 |

Tabela7 Taxa de queima de diâmetro dos tubos de aço

|

Steel |

Diameter flaring rate of steel tubes/% |

||

|

ID/OD |

|||

|

≤0.6 |

>0.6~0.8 |

>0.8 |

|

|

Carbon structural steel |

10 |

12 |

17 |

|

Alloy structural steel |

8 |

10 |

15 |

|

Stainless(heat resistance)steel |

12 |

15 |

20 |

Tabela8 Itens de teste e quantidade de amostragem de tubos de aço

|

Number |

Testing items |

Sampling quantity |

|

1 |

Chemical composition |

1 sample from each furnace |

|

2 |

Tensile test |

1 sample from each of two steel tubes on each batch |

|

3 |

Hardness test |

3 samples taken on 2 steel tubes on each batch |

|

4 |

Impact test |

All |

|

5 |

Hydraulic test |

1 sample from each of two steel tubes on each batch |

|

6 |

Flattening test |

2 samples taken on 2 steel tubes on each batch |

|

7 |

Bending test |

1 sample taken on 2 steel tubes on each furnace |

|

8 |

Flaring test |

2 samples taken on 2 steel tubes on each batch |

|

9 |

Macroscopic examination |

1 sample taken on 2 steel tubes on each furnace |

|

10 |

Non-metallic inclusions |

1 sample taken on 2 steel tubes on each furnace |

|

11 |

Eddy current testing |

All |

|

12 |

Magnetic flux leakage detection |

All |

|

13 |

Ultrasonic testing |

All |

|

14 |

Intergranular corrosion test |

1 sample from each of two steel tubes on each batch |

Tabela A.1 Tabela Comparativa de Grau de Aço Similar

|

No. |

GB |

Similar Steel Grade |

|||

|

ISO |

EN |

ASTM/ASME |

JIS |

||

|

1 |

10 |

- |

P195GH |

A |

STB 340 |

|

2 |

20 |

PH26 |

P235GH |

A-1.B |

STB 410 |

|

3 |

12CrMo |

- |

- |

T2/P2 |

STBA 20 |

|

4 |

15CrMo |

13CrMo4-5 |

13CrMo4-5 |

T12/P12 |

STBA 22 |

|

5 |

12Cr1Mo |

- |

10CrMo5-5 |

T11/P11 |

STBA 23 |

|

6 |

12Cr1MoV |

- |

- |

- |

- |

|

7 |

12Cr2Mo |

10CrMo9-10 |

10CrMo9-10 |

T22/P22 |

STBA 24 |

|

8 |

12Cr5Mo-I |

X11CrMo9-1TA |

X11CrMo5+I |

T5/P5 |

STBA 25 |

|

9 |

12Cr5Mo-NT |

- |

X11CrMo5+NT |

T5/P5 |

STBA 25 |

|

10 |

12Cr9Mo-I |

X11CrMo9-1TA |

X11CrMo9-1+I |

T9/P9 |

STBA 26 |

|

11 |

12Cr9Mo-NT |

- |

X11CrMo9-1+NT |

T9/P9 |

STBA 26 |

|

12 |

07Cr19Ni10 |

X7CrNi18-9 |

X6CrNi18-10 |

TP304H |

SUS 304H TB |

|

13 |

07Cr18Ni11Nb |

X7CrNiNb18-10 |

X7CrNiNb18-10 |

TP347H |

SUS 347H TB |

|

14 |

07Cr19Ni11Ti |

- |

X6CrNiTi18-10 |

TP321H |

SUS 321H TB |

|

15 |

022Cr17Ni12Mo2 |

- |

X2CrNiMo17-12-2 |

TP316L |

SUS 316L TB |

Grupo de Produto : Tubos de aço sem costura

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.